TG Series Termal Interface

TG Series Termal InterfacePyroArk® TG series thermal interface material is a heat dissipation sheet that utilizes the flexibility, temperature durability and electrical insulation properties of silicone.

It is highly flexible, and it can efficiently transfer heat by filling the gap. Also, due to its high flexibility, it is possible to contact multiple heat sources with varying heights at once.

The TG series has a wide operating temperature range of -50 degrees to +200 degrees and has flame resistance equivalent to UL94 V-0 and can be used for a wide range of applications. The thickness is 0.5 mm increments and can be laminated to accommodate various thicknesses.

Structure | MINORU® TG series Thermal Interface Material is a heat dissipation sheet that makes the most of silicone's flexibility, temperature durability and electrical insulation performance. | |

Structure |  | |

Characteristic | *Highly compliant TIM filled with high thermal conductivity filler by taking advantage of silicone flexibility *Stable in a wide temperature range, so can be used in harsh environments such as in-vehicle * Can be used as a shock absorbing compliance connecting material such as shock and vibration absorption | |

Application | ∗ Gap fill at the joint between heat source and heat sink | |

Specification |  | |

Environment | ||

Product | TG15 | TG20 | TG30 | TG40 | TG50 | TG100 | TG120 | Method | |||||||

Thermal Conductivity (W/MK) | 1.5 | 2.2 | 3 | 4 | 5 | 10 | 12 | ASTM D5470 | |||||||

Color | Gray | ||||||||||||||

Hardness | 20-30 | 30-40 | 35-50 | 40 to 60 | shore C | ||||||||||

Specif Gravity (g/cm³) | 2.6 | 2.7 | 2.9 | 3.1 | 3.3 | 5.1 | 5.6 | ||||||||

Volume Resistivity (Ω・cm ) | 1*1013 | ASTM D257-14 | |||||||||||||

Dielectric breakdown (kV/mm) | 8.8 | ≥11 | ASTM D149-09 | ||||||||||||

Dielectric Constant(1MHz) | 4.9 | 4.7 | 4.8 | 4.5 | 6.08 | 6.91 | 6.93 | ASTM D150-11 | |||||||

Tensil strength (psi) | 42 | 48 | 45 | 55 | 50 | ASTM D412 | |||||||||

Elongation | 82% | ASTM D412 | |||||||||||||

Thermal expansivity (ppm/℃) | 63 | 48 | 43 | 41 | IPC-TM-6502.4.24 | ||||||||||

Outgassing(TML) | 0.10% | 0.006% | ASMT E595-07 | ||||||||||||

Outgassing (CVCM) | 0.025% | ASMT E595-07 | |||||||||||||

Frame retardance | V0 | UL94 equivalent | |||||||||||||

Operating temperature (℃) | -50 to 200 | ||||||||||||||

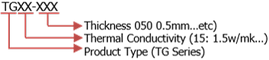

Series | P/N | Thermal Condactivity (W/m・K) | Thickness (um) | Std. Size (mm) |

TG15 | TG15-050 | 1.5 | 500 | 200mm*400mm |

TG15-100 | 1000 | |||

TG15-150 | 1500 | |||

TG15-200 | 2000 | |||

TG20 | TG20-050 | 2.2 | 500 | |

TG20-100 | 1000 | |||

TG20-150 | 1500 | |||

TG20-200 | 2000 | |||

TG30 | TG30-050 | 3 | 500 | |

TG30-100 | 1000 | |||

TG30-150 | 1500 | |||

TG30-200 | 2000 | |||

TG40 | TG40-050 | 4 | 500 | |

TG40-100 | 1000 | |||

TG40-150 | 1500 | |||

TG40-200 | 2000 | |||

TG50 | TG50-050 | 5 | 500 | |

TG50-100 | 1000 | |||

TG50-150 | 1500 | |||

TG50-200 | 2000 |

Series | P/N | Thermal Condactivity (W/m・K) | Thickness (um) | Std. Size (mm) | |||

TG100 | TG100-050 | 10 | 500 | 200mm*400mm | |||

TG100-100 | 1000 | ||||||

TG100-150 | 1500 | ||||||

TG100-200 | 2000 | ||||||

TG120 | TG120-050 | 12 | 500 | ||||

TG120-100 | 1000 | ||||||

TG120-150 | 1500 | ||||||

TG120-200 | 2000 | ||||||

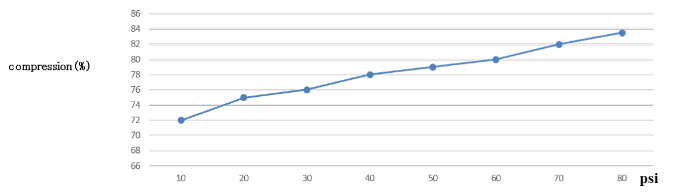

Compression (Psi) vs. thermal conductivity

Typical usage example

By utilizing its thickness and flexibility, TG series enables connection to multiple target devices.

By combining with a heat spreader sheet HCST.CST, it is possible to radiate heat effectively from the Z direction to the X-Y direction.

Storage period

The storage period is two years from the product production date.

The storage conditions are room temperature (22°C, humidity 50% RH)

packaged in the original package.

This product is designed for consumer equipment.

All items and values described here are measured values by our company and are not guaranteed values.

In addition, we do not guarantee the quality after incorporating your device.

Before using the product, be sure to thoroughly study the purpose and conditions of use,

and be sure to conduct a test at your company for confirmation.

In addition, we do not guarantee industrial property rights such as patents regarding usage and purpose.

All numerical values and data presented in this site are example and not warranted at anyway.

Product drawing and specification sheet always represent the latest product information.

Specification and drawing within this site are just for illustrated purpose, not intended as a product specification whatever.

Information presented herein this site may change without prior notification at anytime.

All rights reserved.