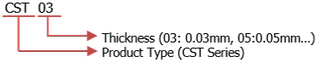

CST Series Heat Spreader

CST Series Heat SpreaderMinoru CST series heat spreader / dissipation EMI shield is a low-cost thermal conduction sheet based on copper foil and newly developed high performance graphene heat conduction layer.

It is possible to make a stable connection to the adherend via the heat conductive adhesive layer. There are wide variety of thicknesses, which enhances the design flexibility when used in combination with other components.

Based on copper foil, it has high EMI shielding characteristics for wide frequency range.

Overview | MINORU® Heat Spreader shield Single-sided copper foil tape CST series is a low-profile product with high EMI shielding properties and heat spreading characteristics. CST has stable shield characteristics in a wide range from 30MHz to 3GHz. | |

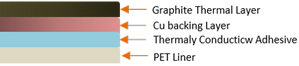

Structure |  | |

Characteristic | * Has high processability such as die cutting. *High heat dissipation characteristics in the XY directions. *As it is a very thin copper foil base, it has high conformability to bent parts. * Flexible and can be attached to curved areas | |

Application | ∗ Electromagnetic wave shield and heat dissipation of ECU etc. ∗ EMI shield for various electronic devices *LCDM EMI and light shield, driver IC heat dissipation | |

Specification |  | |

Environment | CST series are halogen-free products. | |

CST Heat Spreader with Graphene

Product | CST02 | CST03 | CST05 | CST08 | CST10 |

Cu Foil Type | electrolytic | rolling | |||

Black heat dissipation layer (um) | 4±10% | 4±10% | 7±10% | 10±10% | 10±10% |

Cu thickness (um) | 6±10% | 11±10% | 20±10% | 40±10% | 50±10% |

Thermal conductive adhesive (um) | 10±10% | 15±10% | 23±10% | 30±10% | 40±10% |

Total Thickness(um) | 20 (20 to 25) | 30±5 | 50±5 | 80±10% | 100±10% |

Color | Matt Black | ||||

Operating Temperature (℃) | -40 to 125 | ||||

Liner | PET | ||||

| Product | CST02 | CST03 | CST05 | CST08 | CST10 | Method |

热辐射 Infrared Emissivity | 1.1 | ASTM C1371 | ||||

水平方向熱伝導率 X-Y direction Thermal Conductivity (W/m.k) | 811 | 827 | 871 | 891 | 917 | ASTM D5470 |

垂直方向熱伝導率 Z direction Thermal Conductivity (W/m.k) | 4 | 5 | 6 | 7 | 7 | ASTM D5470 |

粘着力 Adhesion (N/25mm,180°) | 8 | 12 | ≥12 | PSTC-1 | ||

粘着保持力 Retention (hours/25mm) @室温 | >48 | PSTC-7 | ||||

体積低効率 Volume Resistance(Ω.cm) | 1013 | ASTM D257 | ||||

密度 Density g/cm³ | 2.9 | 3.2 | 4.1 | 5.3 | 5.9 | |

Electrical conductivity(S/M) | 5.9*108 | 7.7*107 | 8.1*107 | 9.5*107 | 9.5*107 | |

引張强度 Tensile strength | >30N/10mm | |||||

熱容量 Heat capacity (50°C J/g.k) | 425 | 408 | 405 | 397 | 361 | |

耐候性 Weather ability evaluation 1500Hrs | OK | |||||

シールド特性 Shielding Effectiveness | >90dB@(30 MHz to 3 GHz) | MIL-STD-285 | ||||

屈曲特性 Bending (180° R5 U型) | ≥15 | |||||

難燃性 Flame retardant | V0 | UL94 | ||||

CST EMI Shield Characteristics

Storage period

The storage period is two years from the product production date.

The storage conditions are room temperature (22°C, humidity 50% RH)

packaged in the original package.

This product is designed for consumer equipment.

All items and values described here are measured values by our company and are not guaranteed values.

In addition, we do not guarantee the quality after incorporating your device.

Before using the product, be sure to thoroughly study the purpose and conditions of use,

and be sure to conduct a test at your company for confirmation.

In addition, we do not guarantee industrial property rights such as patents regarding usage and purpose.

All numerical values and data presented in this site are example and not warranted at anyway.

Product drawing and specification sheet always represent the latest product information.

Specification and drawing within this site are just for illustrated purpose, not intended as a product specification whatever.

Information presented herein this site may change without prior notification at anytime.

All rights reserved.