81015 Thermal Tape

81015 Thermal TapeMinoru PyroArk® Heat Dissipation Tape 81015 is based on PI film and has high thermal conductivity of 1.36w/mk. Excellent handling characteristics for both die cut and assembly process. Ideal for automotive electronics, medical equipment, and other mission critical application require none-flammability.

Actual usage 610 Series LED

Overview | MINORU® PyroArk® 81015 is a thin PI film based tape that has a high thermal conductivity of 1.36W/mk) across all thickness | |

Structure | ||

Characteristic | *Rework possible *High thermal conductivity *Sufficient bonding strength for adherends such as heat sinks | |

Application | *LED light bar installation and heat dissipation measures ∗ Joining of heat source and heat sink ∗ Graphite and other heat equalizing sheet and target Z-Axis heat dissipation joint ∗ Attached metal foil EMI shield, as a heat radiation EMI shield composite product | |

Specification |  | |

Environment | 710xx Series are halogen-free products. | |

Item | Value | Method | |||

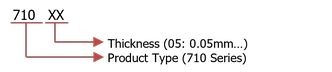

Product | 61005 | 61010 | 61015 | 61020 | |

Thermal conductivity (W/m.k) | 1.36 | ASTM D5470 | |||

Color | White | ||||

Thickness (um) | 50±10% | 100±10% | 150±10% | 200±10% | |

Adhesive | Filled Acrylic Polymer | ||||

Filler | Ceramic | ||||

Liner | Film | ||||

Dielectric Strength (KV) | 2.9 | 3.1 | 3.3 | 3.7 | ASTM D149 |

Specific Gravity g/cm³ | 1.69 | ||||

Tensil Strength (Mpa) | 9.1 | 9.6 | 10.1 | 10.7 | ASTM D3654 |

Adhesive Strength (N/25mm,180°) | 6 | 8 | 12 | 15 | PSTC-1 |

Adhesive Strength (N/25mm,180°) | >48 | PSTC-7 | |||

Volume Resistivity (Ω.cm) | 1*1013 | ASTM D257 | |||

Thermal resistance (℃·in2/W,50 psi) | 0.5 | ASTM D5470 | |||

Operating Temperature(°C) | -40 to 150 | ||||

Storage period

The storage period is one years from the product production date.

The storage conditions are room temperature (22°C, humidity 50% RH)

packaged in the original package.

This product is designed for consumer equipment.

All items and values described here are measured values by our company and are not guaranteed values.

In addition, we do not guarantee the quality after incorporating your device.

Before using the product, be sure to thoroughly study the purpose and conditions of use,

and be sure to conduct a test at your company for confirmation.

In addition, we do not guarantee industrial property rights such as patents regarding usage and purpose.

All numerical values and data presented in this site are example and not warranted at anyway.

Product drawing and specification sheet always represent the latest product information.

Specification and drawing within this site are just for illustrated purpose, not intended as a product specification whatever.

Information presented herein this site may change without prior notification at anytime.

All rights reserved.