GripTight®️ High Bonding Tape

GripTight®️ High Bonding Tape GripTight®️High Bonding Tape 56 Series is based on viscoelastic acrylic foam that offer energy absortion and stress relaxing properties to offer unique characteristics to the product. Series work with wide range of surface mateials with reliable bonding characteristics far exceeding the normal temparature range of normal acrylic adhesive tape. Ideal for automotive, medical, and architecture shere reliable longlasting bonding is required.

Overview | GripTight® Line of 56 series acrylic foam adhesive tape offers high bonding for multiple surface with good shock and vibration dumping as well as offer superior coplanarity to uneven surfaces. | |

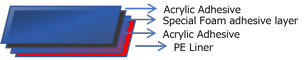

Structure |  | |

Characteristic | ∗ Comply height cariation by soft acrylic foam substrate for strong bonding ∗ Strong bonding based on both mechanical characteristics ^ specially developped adhesive * Automated die cut process friendly | |

Application | *Automotive exterior parts affiation *Display cover attachment with strong bonding and shock absorption *Building project and other structural affixation | |

Specification |  | |

Environment | 56 Series is a halogen free product. | |

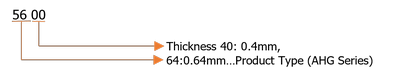

P/N | 5640 | 5664 | 5680 | 56110 |

Thickness (mm) | 0.4 | 0.64 | 0.8 | 1.1 |

Color | Black | Black | Black | Black |

Density | 0.67g/cm³ | 0.71g/cm³ | 0.75g/cm³ | 0.79g/cm³ |

Peel Adhesion 90° (N/cm) | 24 | 34 | 41 | 47 |

Dynamic Shear (N/cm²) | 109 | 110 | 101 | 96 |

Tensile Strength (N/cm²) | 81 | 72 | 65 | 64 |

90 degrees peeling force:

The patch SUS 304, the adhesive surface is fitted with aluminum foil 130um thickness, pressed back and forth 2 times with a 2kg roller, set at room temperature for 72 hours, stretching speed of 300mm/min

Dynamic shear strength:

The patch SUS 304, pressed back and forth 2 times with a 2kg roller, was set at room temperature for 72 hours and stretched at a speed of 300mm/min

Stretch strength:

The T-shaped treatment is attached, pressed back and forth 2 times with a 2kg roller, set at room temperature for 72 hours, and stretch speed of 300mm/min

Dynamic Shear: N/cm³ | Temperature | 5640 | 5664 | 5680 | 56110 |

-40° | 189 | 393 | 353 | 321 | |

-20°C | 184 | 187 | 349 | 317 | |

0°C | 156 | 151 | 142 | 136 | |

23°C | 109 | 110 | 101 | 96 | |

50°C | 69 | 76 | 79 | 67 | |

75° | 40 | 46 | 41 | 36 | |

100°C | 23 | 30 | 25 | 22 | |

125°C | 18 | 19 | 17 | 16 |

Material | 5640 | 5664 | 5680 | 56110 |

Aluminum alloy | 24 | 34 | 41 | 47 |

| Boned steel plate | 25 | 35 | 41 | 47 |

ABS resin | 28 | 35 | 42 | 48 |

Acrylic resin | 27 | 35 | 42 | 48 |

Polystyrene resin (PS) | 28 | 35 | 42 | 49 |

Hard PVC resin | 28 | 34 | 43 | 48 |

Polycarbonate resinv(PC) | 28 | 35 | 42 | 49 |

Polyethylene (PE) | 7 | 9 | 12 | 13 |

Polypropylene (PP) | 7 | 7 | 8 | 8 |

Glass | 28 | 35 | 42 | 48 |

1) Firm application pressure helps develop better wet-out and adhesive contact and may lead to improved bond strength as well as electrical conductivity. Pressure must be applied to the bond area after assembly to ensure sufficient wet-out of the 56110 adhesive to the substrates and to engage the conductive acrylic adhesive fillers with the substrates to make electrical connection. Mechanical pressure (roller, metal bar) or finger pressure at 5-15 psi.

(Optimally the application conditions are determined via a set of Design of Experiments (DOE) using a range of application pressures, dwell time and temperatures (suggested initial range might include 5-15psi, 2-5 seconds, 21°C- 38°C).

2) Heat may be applied simultaneously with pressure to improve wetting, final bond strength and electrical conductivity. Suggested temperature range to evaluate is in the 38°C-60°C range.

3) To obtain optimum adhesion, the bonding surfaces must be clean, dry and well unified. Some typical surface cleaning solvents are isopropyl alcohol or heptanes.

Storage period

The storage period is two years from the product production date.

The storage conditions are room temperature (22°C, humidity 50% RH)

packaged in the original package.

This product is designed for consumer equipment.

All items and values described here are measured values by our company and are not guaranteed values.

In addition, we do not guarantee the quality after incorporating your device.

Before using the product, be sure to thoroughly study the purpose and conditions of use,

and be sure to conduct a test at your company for confirmation.

In addition, we do not guarantee industrial property rights such as patents regarding usage and purpose.

All numerical values and data presented in this site are example and not warranted at anyway.

Product drawing and specification sheet always represent the latest product information.

Specification and drawing within this site are just for illustrated purpose, not intended as a product specification whatever.

Information presented herein this site may change without prior notification at anytime.

All rights reserved.