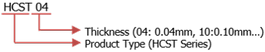

HCST Series Graphene Heat Spreader

HCST Series Graphene Heat SpreaderThe heat spreader/diffusion sheet HCST series has higher thermal conductivity in the X-Y directions than the artificial graphite products (1700-1900W/mk) and is a product with high EMI shielding properties because of Cu substrate.

Unlike graphite products, there is no need to perform pouch processing when performing die cutting, which is a great advantage in product and reduce the manufacturing costs. ‥

High thermal conductivity and shielding properties make it an ideal backing material for film-based OLED displays.

HCST Heat Spreader with Graphene

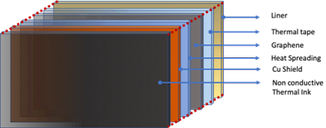

Overview | MINORU® The composite heat spreader HCST series is a copper foil/graphene-based product with extremely high thermal conductivity in the X and Y directions. | |

Structure |  | |

Characteristic | *High shielding property based on copper foil (>90dB@30 MHz to 3 GHz) *Comes with high thermal conductivity adhesive ensure good contact with the heat source with strong & stable adhesion. *Since the die cutting process does not require pouch processing, the process is simple. | |

Application | ∗ As a heat spot countermeasure * Prevents discoloration due to LCD display temperature ∗ Replaces BLS etc. as EMI shield + heat dissipation | |

Specification |  | |

Environment | HCST series are halogen-free products. | |

Item | Value | Method | |||

Product | HCST04 | HCST06* | HCST08* | HCST10* | |

Infrared emissivity | 1.1 | ASTM C1371 | |||

Thermal Conductivity XY-Axis (W/m.k) | 1780 | 1810 | 1890 | 1910 | ASTM D5470 |

Thermal Conductivity Z-axis (W/m.k) | 21.5 | 20.1 | 19.3 | 18.2 | ASTM D149 |

Adhesive Strength (N/25mm,180°) | 9±1 | 10.5±1 | 12±2 | 13±2 | PSTC-1 |

Adhesive holding power (hours/25mm) | >48 | PSTC-7 | |||

Volume Resistivity (Ω.cm) | 1*1013 | ASTM D257 | |||

Weatherbility 1500Hrs | OK | ||||

Shield Property | >90dB@(30 MHz to 3 GHz) | MIL-STD-285 | |||

Operating Temperature (℃) | -40 to 100 | ||||

Frame retardance | V0 | UL94 | |||

RoHS, Halogen free | Pass | SGS | |||

*HCST06, 08, 10:We are currently suspending sales of aforementioned items due to raw material availability. | |||||

Temperature rise of HCST with respect to room temperature is 27.8℃, artificial graphite is 30.7℃

HCST composite material suppresses 2.9℃ temperature rise compared to artificial graphite

Comparison

Storage period

The storage period is two years from the product production date.

The storage conditions are room temperature (22°C, humidity 50% RH)

packaged in the original package.

This product is designed for consumer equipment.

All items and values described here are measured values by our company and are not guaranteed values.

In addition, we do not guarantee the quality after incorporating your device.

Before using the product, be sure to thoroughly study the purpose and conditions of use,

and be sure to conduct a test at your company for confirmation.

In addition, we do not guarantee industrial property rights such as patents regarding usage and purpose.

All numerical values and data presented in this site are example and not warranted at anyway.

Product drawing and specification sheet always represent the latest product information.

Specification and drawing within this site are just for illustrated purpose, not intended as a product specification whatever.

Information presented herein this site may change without prior notification at anytime.

All rights reserved.